Powder Feeder

In addition to standard powder feeders, we can also develop customized solutions that can be easily integrated into various types of coating systems.

For ultrafast laser metal deposition made to measure

The ACunity Powder feeder guarantee stable high performance and a unique high-precision micro powder feed function. Their modular design offers the user enough space to choose between a single bottle up to a maximum of four bottles, depending on the needs of the process. The powder bottle can also be fully customized, divided into 0.75 l, 1.5 l and 5 l to meet the requirements of EHLA technology.

Sensor technology facilitates control and operability

The powder feeder is equipped with a special seal that can save 10-20 % of gas consumption compared to similar products on the market. The stirring function in the powder bottle can be set at intervals or continuously via the integrated touchscreen user interface. Each powder bottle is equipped with a powder level sensor that automatically indicates when the powder level is low so that the user can easily refill the powder. The special coating of the powder tray makes it more wear-resistant and durable, reducing the frequency of consumable replacements.

Technical Data

Rotary plate

– Turntable: 0.2-10 rpm continuously adjustable

– Speed accuracy: ± 0.08 %

– Mixer: optional

– Powder plate type: 3.5 mm / 5 mm / 7.5 mm / 11 mm / 16 mm

Powder carrier gas

– Gas type: Argon 4-6 bar

– Gas flow rate: 0-10 l (adjusted depending on type) ± 1 % (depending on type)

– Outlet pressure: 1.5 bar

Powder

– Particle size: 20-200 µm (varies slightly depending on powder type)

– Feed rate: approx. 2-250 g/min

– Measuring accuracy: ± 1 % (varies slightly depending on powder and process)

– Protection class / safety standard: IP 54

– Optional configuration: Digital signal I/O-Profinet

Powder hopper

Capacity of a single hopper: 1.5 l / 5 l / 7.5 l

Control

– Display: Imported control system

– PLC: Imported CNC system

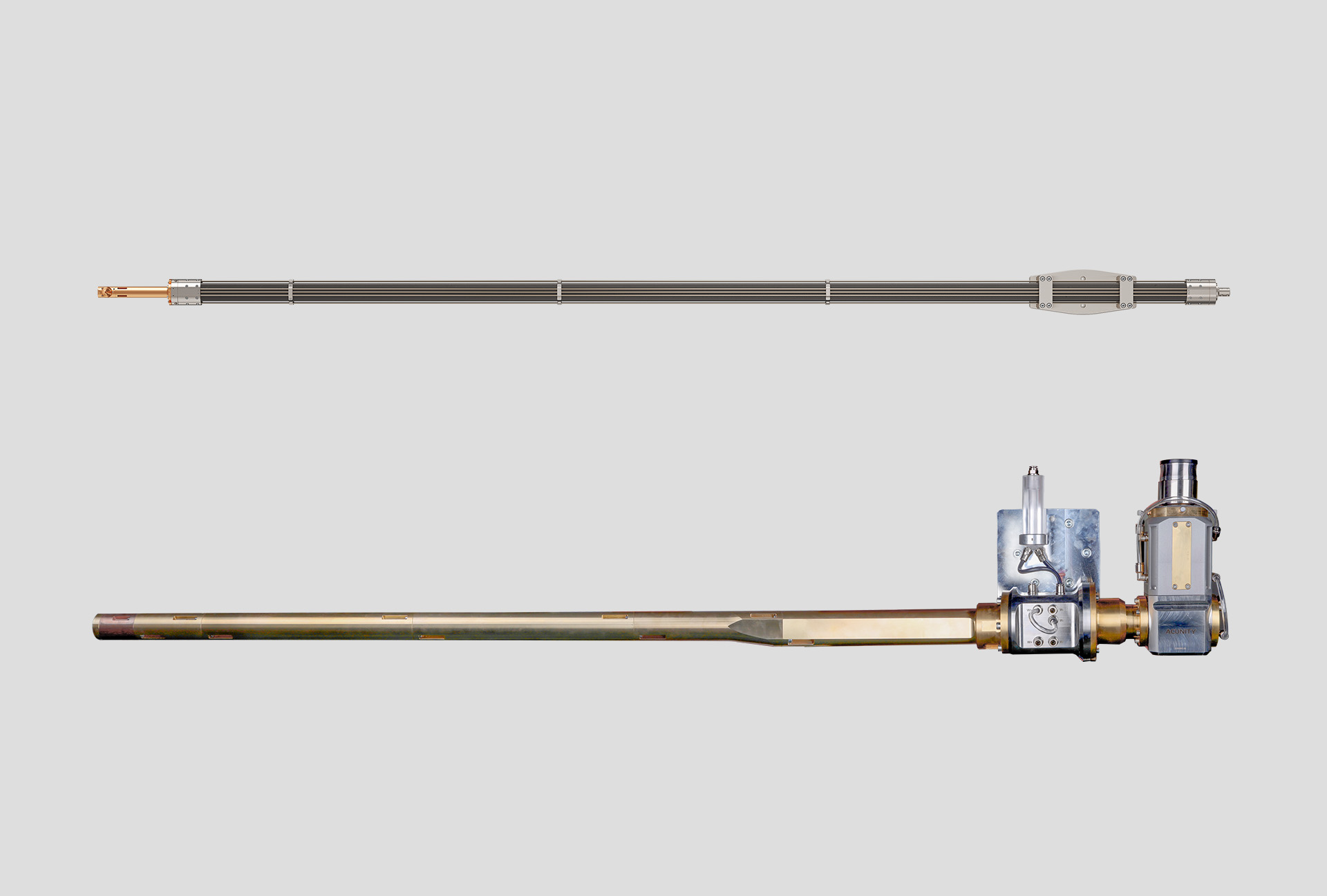

EHLA Optics & Powder Nozzles

Modularity is our strength. It is based on years of experience in hardware development. All core components of our systems can be combined and upgraded in a practical way.

Variety in design for different applications

The EHLA optics and powder nozzles have been developed for high-power lasers. The processing heads specially designed for external coating guarantee robust operation in EHLA and LMD processes with high performance.

The ACunity series nozzles for internal coating have been specially developed for laser metal deposition, repairing and hardening the internal surfaces of parts. They integrate laser, powder, gas and cooling water elements in a very small spatial structure.

Laser Processing Head

Powder feed nozzle with integrated optics for external coating

- Versatile design for various applications

- Designed for reliable and robust operation in high power EHLA and LMD processes

- Integrated cooling and gas channels for improved efficiency and process control

- Suitable for a wide range of powder materials, including iron-based, nickel, cobalt, ceramics and more

- Precise powder feed with ACunity powder feeder

- Powder nozzles are easy to change - convenient for different application scenarios

- Flexible spot size range - allows adaptation to a variety of spot sizes

- Compatibility with various laser sources

Immersion Depth up to 4.5 Meters

Laser processing heads especially for internal coating

- Cooling, laser, powder and gas channels are compactly integrated in a single tube - this system therefore offers optimum functionality

- The modular structure of the design improves adaptability and versatility

- The processing diameter can be significantly reduced to up to 33 mm

- Significant weight reduction through the use of carbon fiber reinforced plastic (CFRP)

- Reaches a depth of up to 4.5 meters and thus offers thorough and comprehensive processing options