Laser Technologies

for the Industry

Precision Drilling

and Cutting

Surfaces Quickly

and Precisely

ACunity GmbH

We provide our customers with comprehensive solutions for the entire production chain in the fields of laser metal deposition, laser welding, and additive laser manufacturing. This includes developing both the equipment and hardware as well as the processes.

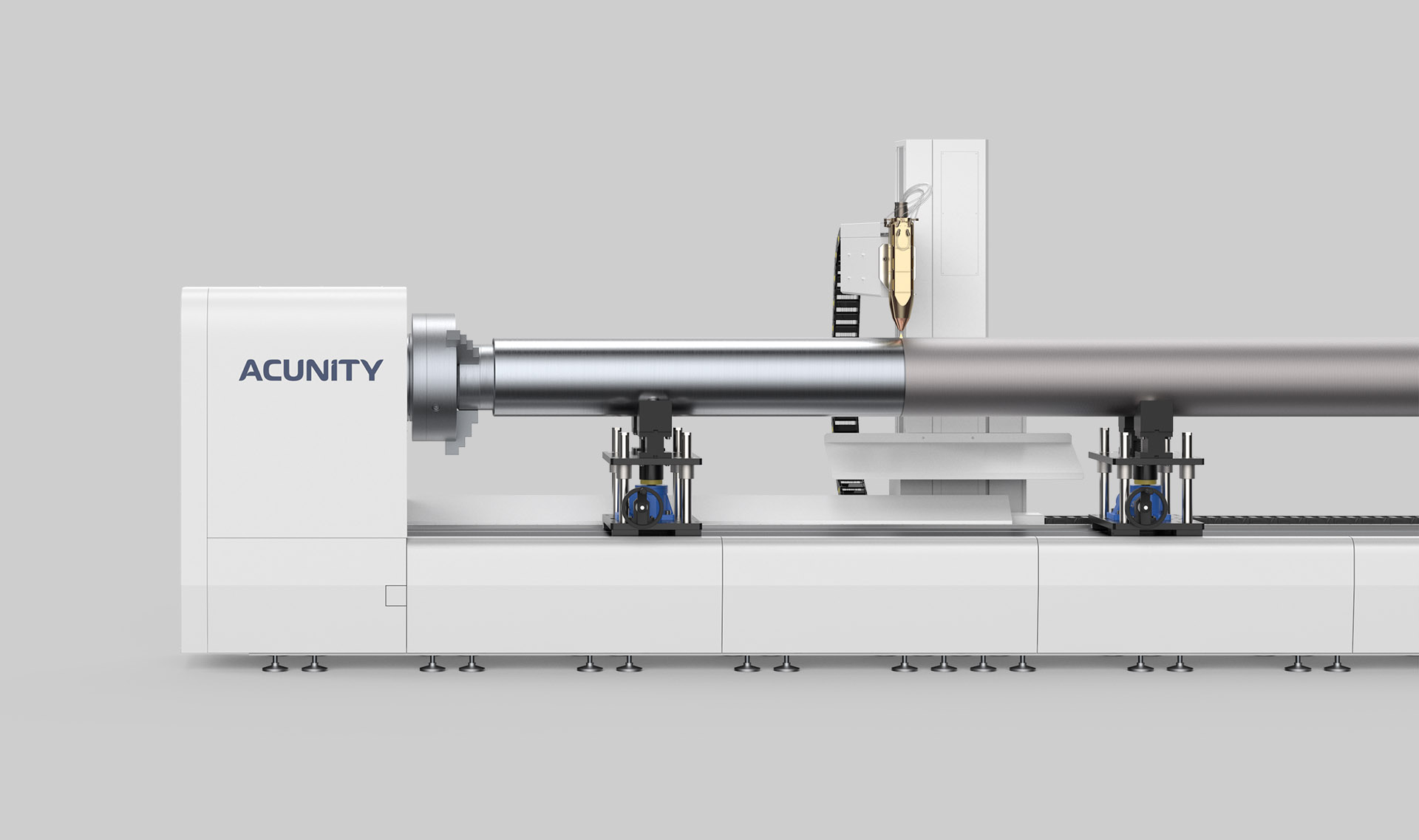

The EHLA System

The technology of extreme high-speed laser metal deposition (EHLA) is employed to protect metallic components from wear and corrosion effectively, in an environmentally and material-friendly manner. We offer one of the world's most powerful EHLA machine systems, along with the corresponding process expertise. Our modular, customizable machines enable flexible coating, repair, or additive manufacturing to become an in-house solution for you.

EHLA Technology

Thin layers can be applied to surfaces in a resource-efficient and material-preserving manner – for optimal wear and corrosion protection of components.

EHLA Components

The powder feeders we have developed are part of the EHLA system. They ensure consistently high performance and a highly precise micro-powder delivery function.

Application / Industries

The powerful ACunity EHLA system offers standard and customized solutions for almost all industries and sectors. The areas of application are expanding rapidly.

Laser Drilling

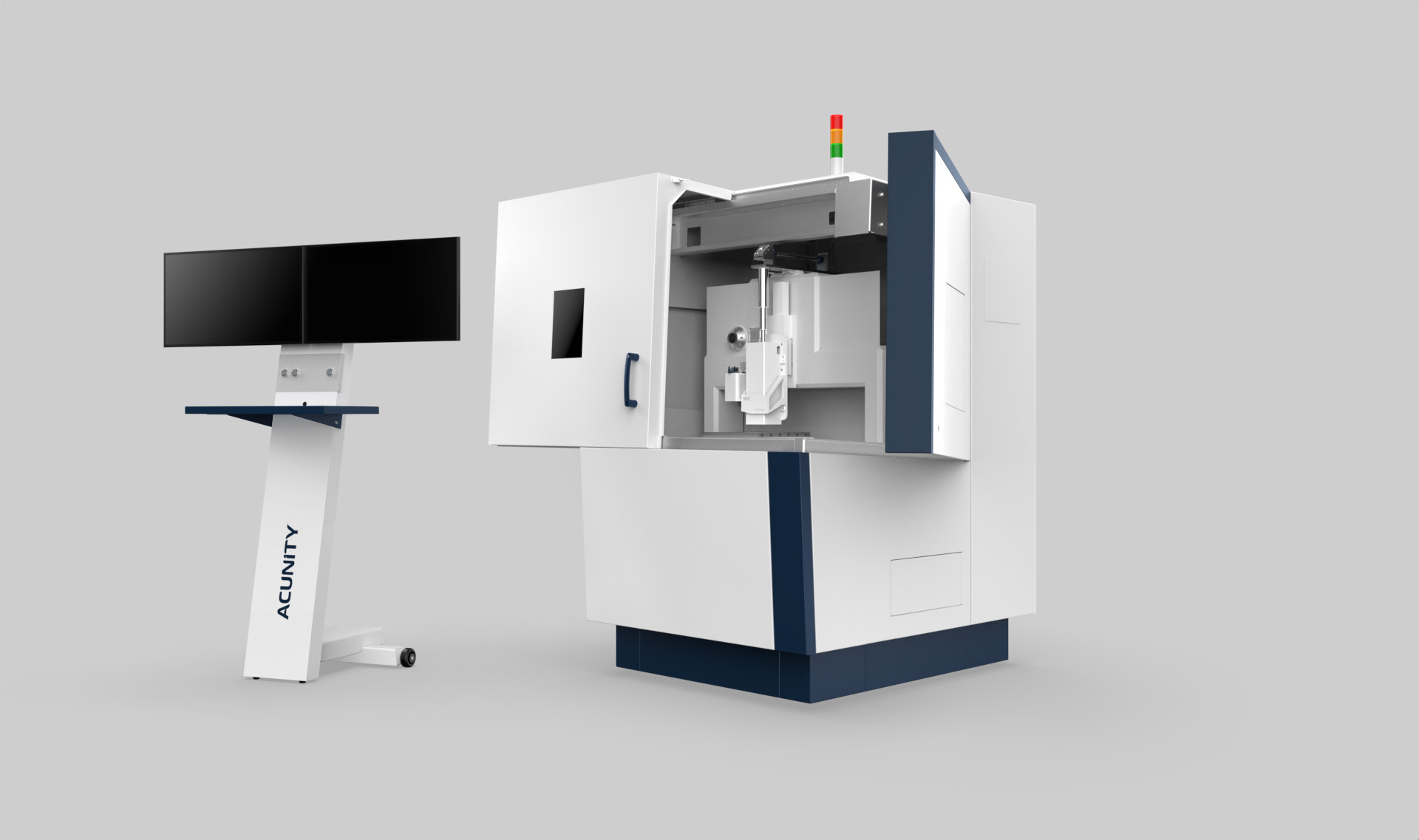

Laser drilling using ultra-short pulsed laser radiation and special optics, such as helical drilling laser optics, enables the drilling of any material with the highest precision and quality. Hole geometries such as diameter and conicity can be infinitely adjusted even for the smallest holes in the range of less than 20 µm with high aspect ratios of up to 1:30 (hole diameter to material thickness). This technology can also be used analogously for laser cutting. Our modular system concepts enable this production technology to be integrated into a variety of state-of-the-art laser processing systems, which can be adapted to specific customer requirements.

Technological Background

The quality requirements for aperture size and gap width in precision drilling and cutting have increased immensely due to the technological trend towards miniaturization.

System Integration

We offer you three high-performance service packages: from the integration of high-tech systems and components into your company to contract manufacturing.

Application / Industries

Laser drilling and cutting enables complex and high-precision drilling and cutting that can be used in many industrial sectors.