EHLA Technology

Process is Economical, Resource and Environmentally Friendly

The technology of extreme high-speed laser metal deposition - is used to protect the surface of metallic components from wear and corrosion in an effective, environmentally friendly and material-friendly manner. Better options for repair and surface modifications can significantly extend the service life of these components. In terms of cost, efficiency and thermal effects on the material, the environmentally friendly EHLA process is an irreplaceable application in many industrial sectors.

Innovation in Process Control

Powder particles melt directly in the laser beam

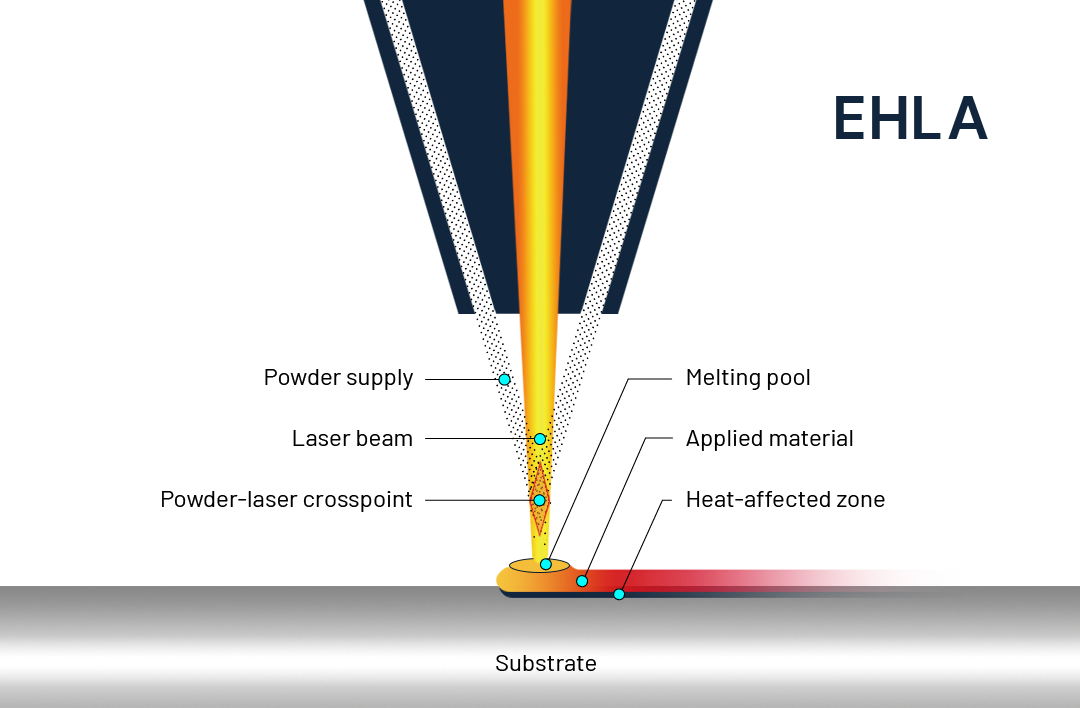

EHLA is a further development of conventional laser metal deposition. This technology owes its breakthrough largely to an innovation in process control that enables much higher coating speeds. The new approach is to completely liquefy the powder particles before they hit the surface of the workpiece.

EHLA is a synchronized powder feed process in which the relative position of the powder's focal plane and that of the laser are adjusted so that the cladding powder intersects and melts the laser beam above the substrate and is then evenly applied to its surface. After rapid solidification, the cladding layer has a very thin coating and is metallurgically bonded to the substrate.

Advantages compared to conventional laser metal deposition

The main difference to conventional laser metal deposition is the change in the melting position of the powder. With EHLA, the molten powder material falls onto the surface of the substrate and not the solid powder particles, so that the deposition welding speed is significantly increased. With conventional laser metal deposition a cladding speed of 0.5 to 2.0 m/min is usually achieved, with EHLA from 20 to 200 m/min. This corresponds to an increase of 40 to 100 times. This technology can therefore be used to coat large-area parts.

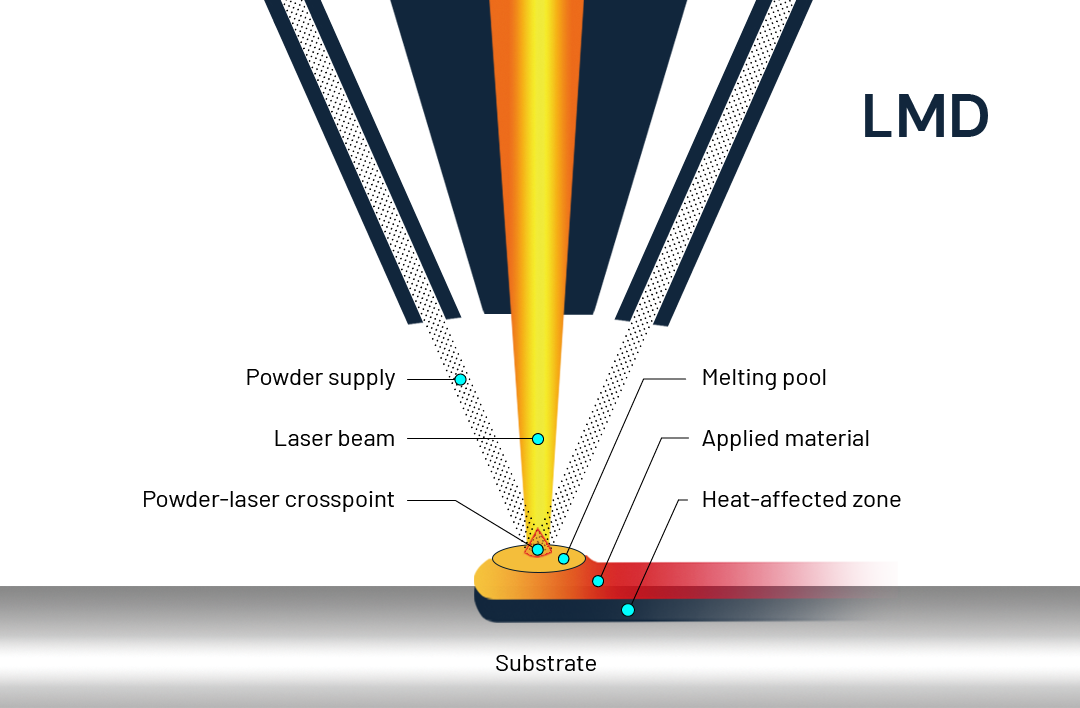

Melting Position of the Powder

A process comparison between conventional laser metal deposition and EHLA

New Material Combinations are Possible

The component hardly heats up

Due to the very high melting speed, the energy density is lower. The powder melted over the substrate absorbs a large proportion of the laser energy, so that the heat input is significantly lower with EHLA. This means that new material combinations can be used and even heat-sensitive components can be coated where this was previously not possible due to the high heat development.

The coating produced with EHLA is smoother and more homogeneous. It requires fewer subsequent processing steps. The roughness is reduced to a tenth of the value typical for laser deposition welding.

The very economical use of material also speaks in favor of EHLA. The thickness of the coating produced with conventional laser metal deposition is usually more than 0.5 mm, while the thickness of the coating produced with EHLA is between 0.05 and 1 mm.

EHLA – The Benefits at a Glance

- Efficient use of material and energy

- Suitable for tough and hard coatings

- Suitable for almost all steels, cast iron and aluminum alloys

- Very high interlayer adhesion due to metallurgical bonding

- Various powders can be used

- Extremely thin, smooth and wear-resistant coatings

- Extremely low thermal load on the workpiece

- Excellent environmental compatibility

- Fast working speeds

A Broad Field for Future Research

Valuable benefits for the environment and enormous economic potential

The high melting performance and good coating quality of EHLA have prompted domestic and foreign scientists to research and study this process. Its continuous application in industrial production depends not only on its unique technical advantages, but also on its good environmental benefits and enormous economic potential. Because thinner layers can be applied much faster, more precisely and with less heat input, completely new areas of application are opening up, for example in the coating of brake disks and in the repair of heat-sensitive components such as landing gear parts in aviation.

The most important future research priorities are the development of EHLA for flat and free-form surfaces, the research and development of new build-up welding materials and further research into this process in combination with additive manufacturing. The aim is to expand the scope of application of EHLA technology in surface treatment, to further optimize coating quality and to accelerate the development of additive 3D manufacturing technology, which will drive the industrial application of 3D printing technology for metals to a large extent in the future.

Technological

Background

A project by the Fraunhofer Institute and RWTH Aachen University

Between 2013 and 2017, researchers at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT) and RWTH Aachen University developed this process for repairing metal parts with coatings - the EHLA process. Following their proposal, this technology was noticed by numerous scientists and researchers and gradually replaced the original hard chrome plating. The areas of application are expanding rapidly. EHLA is patented and award-winning.

The time was ripe for a new technology

To protect highly stressed metallic components - rollers, hydraulic cylinders, pistons, discs or bearings - from corrosion and wear, coating processes such as hard chrome plating, thermal spraying or laser metal deposition have been used up to now. All three have disadvantages: The use of environmentally harmful chemicals (chromium VI), low coating adhesion, cracking, spalling or high post-processing costs.

These shortcomings and the fact that chromium VI can only be used in the EU with special approval have increased the demand on the market for an efficient and clean alternative for wear and corrosion protection. A switch to a new technology with which coatings can be applied economically and in an environmentally friendly manner was inevitable. Extreme high-speed laser metal deposition offered the solution and also scored with significant advantages.