HDO v7

Helical Drilling Optics

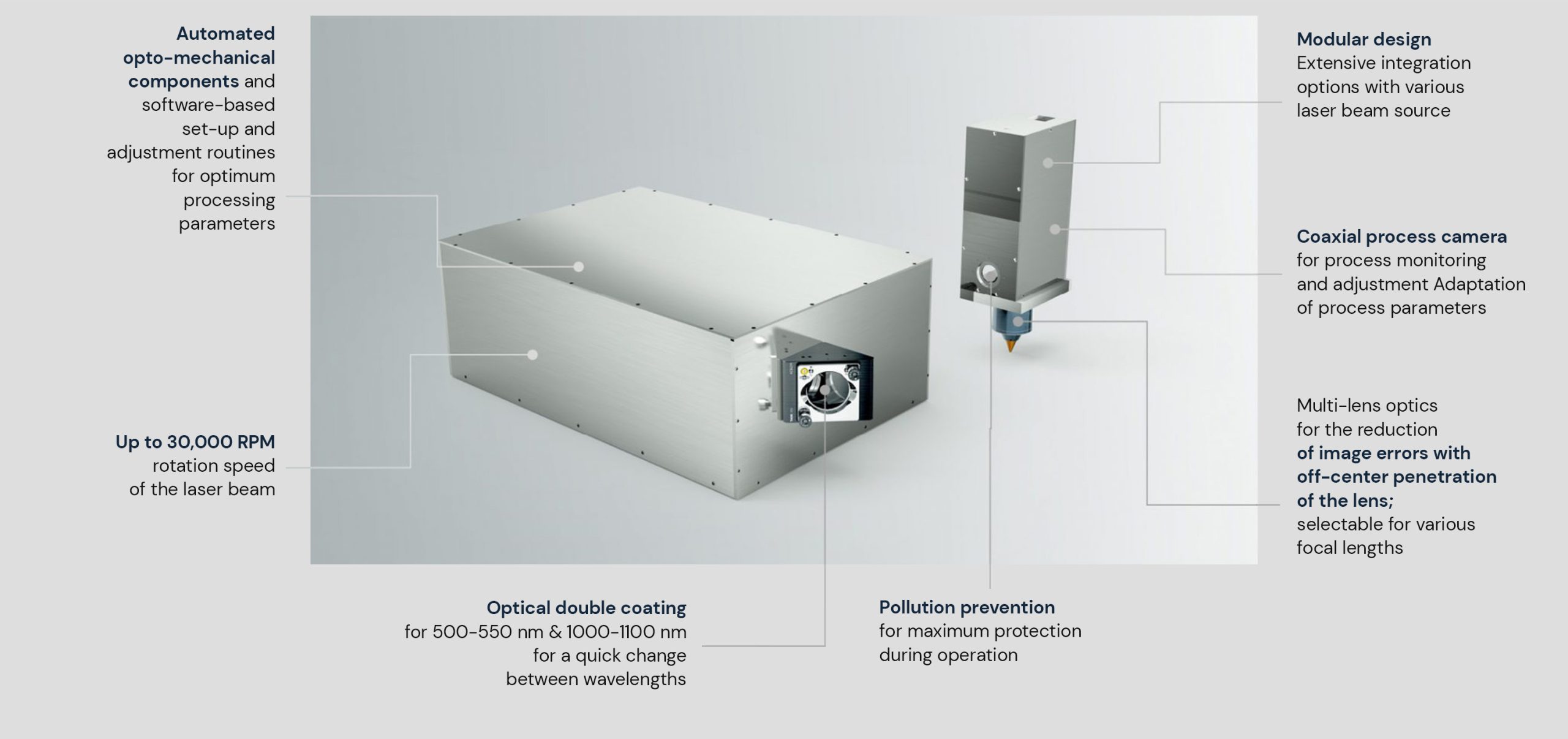

Outstanding Features of the Laser Helical Drilling System (HDO)

- Easy to integrate into any laser processing system thanks to the modular design with the compact process head

- High-precision adjustment of drilling diameter and drilling angle

- High aspect ratios of up to 1:30 (ratio of bore diameter to bore length) thanks to multi-reflections and inherent rotation of the laser beam

- Highly productive due to extremely high rotation speeds of up to 30,000 rpm (optical)

- Double coating for 500-550 nm & 1000-1100 nm for fast switching between two wavelengths

Drilling in 0.5 mm thick stainless steel

Technological Principle

Achieving uniform and precise round drilling outcomes

The laser helical drilling system consists of a beam rotator (hollow shaft motor) and optical components for laser beam displacement and tilting. The laser beam is rotated around the optical axis by the image rotator so that the laser beam is guided along a helical path relative to the workpiece surface. The image rotator (Dove prism) is mounted in a high-precision hollow shaft motor. If the laser beam is deflected or tilted relative to the optical axes, bores with different bore diameters and adjustable conicity can be produced. By using intuitive software, the target parameters of diameter and taper can be precisely set.

The use of a Dove prism provides an unrivaled process advantage in that the optical rotation of the laser beam relative to its position on the helical path achieves qualitative independence from the laser beam profile and thus a consistently round drilling result can be achieved. In addition, the optical rotation speed is twice as high as the mechanical rotation speed of the hollow shaft, which contributes to process efficiency.

Main functionality

Helical Drilling Optics v7

Modular Design

Extensive integration options with various laser beam source

Rotation Module

- Dimensions: (LxWxH) - 555x370x195 mm

- Weight: 30 kg

- Maximum rotation speed: 30,000 rpm

- Hollow shaft motor with encoder for discrete positioning speed and temperature control, water cooling optional

- Fused silica triplet lens system optical elements partially double-coated (VIS+IR)

- Achievable filament diameters: 5-1000 µm

- Achievable conicities: max. ±15°

- Rotation axis for polarizer with an accuracy of 0.75 arcmin

- Motorized mirror deflector for automated adjustment routines

Focusing Module

- Dimensions: (LxWxH) - 145x105x280 mm

- Weight: 4 kg

- Coaxial CMOS camera

- Real-time observation

- Fixed optics, focal lengths of 30, 60, 120, 150 mm, etc.

- Highest stability requirements and reproducibility

- Usable wavelengths: 355 nm, 532 nm and 1064 nm

The Advantages of Laser Helical Drilling

Based on Ø 100 µm holes in 1 mm thick steel, with a focus on quality

Parameters

HDO

long-pulse drilling

Electrical discharge machining

Drilling speed

1 Sec./hole

0,3 Sec./hole

0,5 Sec./hole

Precision

< 1 μm

- 5 μm

> 30 μm

Heat-affected zone

negligible

5 μm

20 μm

Aspect ratio

50:1

10:1

10:1

Conicity

-14°~15°

3-15°

3-8°

Roughness of the drill wall

< 0,2 µm

2 µm

10 µm

Roundness of the drill exit

> 0,95

~ 0.65

0,75

Technological Background

The quality requirements for aperture size and gap width in precision drilling and cutting have increased immensely due to the technological trend towards miniaturization.

In this context, high-precision helical drilling optics (HDO) was invented, which, in combination with ultra-short laser beams, offers the best processing technology for metallic and non-metallic materials. In addition, HDO offers the flexibility and process stability of defined drilling diameters and conicity for micro-drilling and kerfing.

Three wavelength ranges: UV, Green and IR

Since its first introduction to the global market in 2008, helical drilling technology has undergone several optical and system developments to make it suitable for current and future higher processing requirements.

Today's seventh generation HDO v7 can be used in three different wavelength ranges: UV, green and IR. In addition, the HDO v7 successfully uses a modular design where the rotating core module and the observation module are separated for processing and the interface has been standardized to allow full integration into various processing systems.

The HDO v7 is emerging as a key device for a variety of applications for micro-holes in high-value products such as turbine blades and functional surfaces.

Why helical drillingtechnology?

Aspect ratio

> 30:1

Roundness

> 0.94

Precision

< ± 2 µm

Conicity

± 15°

Answers to Important Questions

What minimum hole diameters can be achieved with different material thicknesses using the HDO? What aspect ratio (ratio between hole depth and hole width) results from this?

With helical drilling technology, holes with a diameter of 10 µm can be produced in material thicknesses of 100 µm. The maximum achievable aspect ratio depends on the material thickness.

Examples

Material thickness: 0.1 mm - aspect ratio: 10:1

Material thickness: 1 mm - aspect ratio: 30:1

Material thickness: 3 mm - aspect ratio: 50:1

What conicities can be achieved with laser helical drilling?

Positive and negative tapers with maximum wall angles of +/-15° can be achieved. Cylindrical holes with high aspect ratios are also possible in all materials.

Which materials can be processed with laser helical drilling technology?

In combination with an ultra-short pulsed laser beam source, even sensitive materials can be processed regardless of the material.

Can right-angled holes be produced using helical drilling optics (HDO)?

Laser helical drilling is limited to the production of round holes. With the addition of a precise planar axis system, contour cuts can be made and thus complex structures such as rectangular profiles or gear profiles with adjustable cutting walls can be produced.

Which laser beam sources can be combined with helical drilling optics?

For the best possible drilling quality, we recommend using an ultra-short pulsed laser beam source with pulse durations of less than 15 ps. In terms of wavelength, IR (1010-1070 nm) laser beam sources as well as VIS (510-540 nm) or UV (340-360 nm) can be used.

How is the HDO integrated into a production machine?

The HDO consists of the rotation module and the focusing module. The rotation module can be fixed statically and placed horizontally in the machine, while the focusing module (weight approx. 4 kg) can be mounted on a braked Z-axis to set the focus for various components.