Laser-Technologien

für die Industrie

Präzisionsbohren

und -schneiden

schnell & präzise

bearbeiten

ACunity GmbH

Wir bieten unseren Kunden Komplettlösungen für die Produktionskette in den Bereichen Laserauftragschweißen, Laserschweißen und additive Laserfertigung, einschließlich der Entwicklung von Ausrüstung und Hardware sowie der Prozessentwicklung.

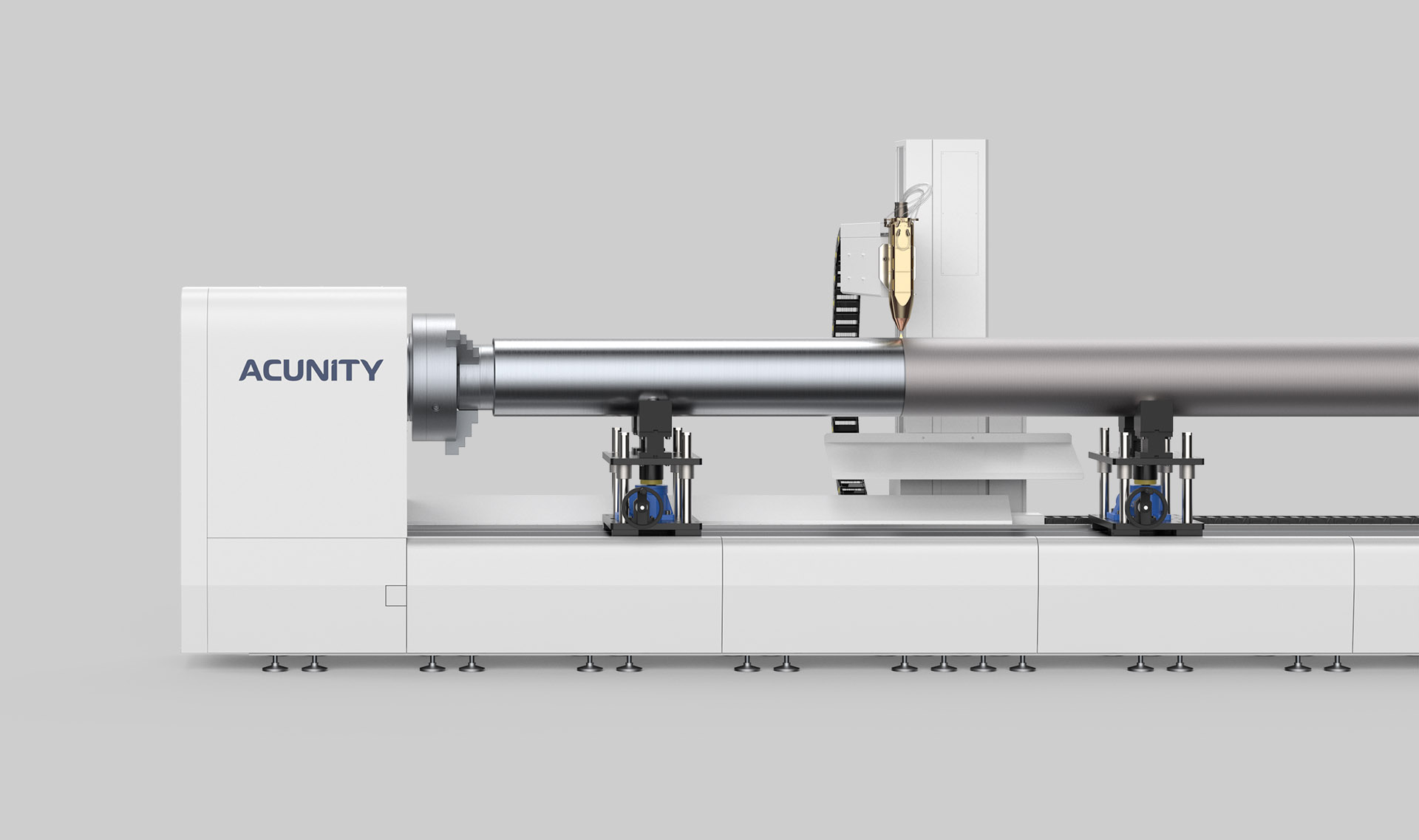

Das EHLA System

Die Technologie des extremen Hochgeschwindigkeits-Laserauftragschweißens wird eingesetzt, um die Oberfläche von metallischen Bauteilen effektiv, umwelt- und materialschonend vor Verschleiß und Korrosion zu schützen. Wir bieten Ihnen eines der weltweit leistungsstärksten EHLA-Maschinensysteme und das entsprechende Prozess-Knowhow. Mit unseren modular anpassbaren Maschinen wird das flexible Beschichten, Reparieren oder additive Fertigen für Sie zur Inhouse-Lösung.

EHLA Technologie

Dünne Schichten können ressourceneffizient und materialschonend auf Oberflächen auftragen werden – für einen optimalen Verschleiß- und Korrosionsschutz von Bauteilen.

EHLA Komponenten

Die von uns entwickelten Pulverförderer sind Teil des EHLA-Systems. Sie gewährleisten eine stabil hohe Leistung und eine hochpräzise Mikro-Pulverzufuhrfunktion.

Anwendung / Branchen

Das leistungsstarke ACunity-EHLA-System bietet Standard- und individuelle Lösungen für nahezu alle Industrien und Branchen. Die Einsatzgebiete vergrößern sich rasant.

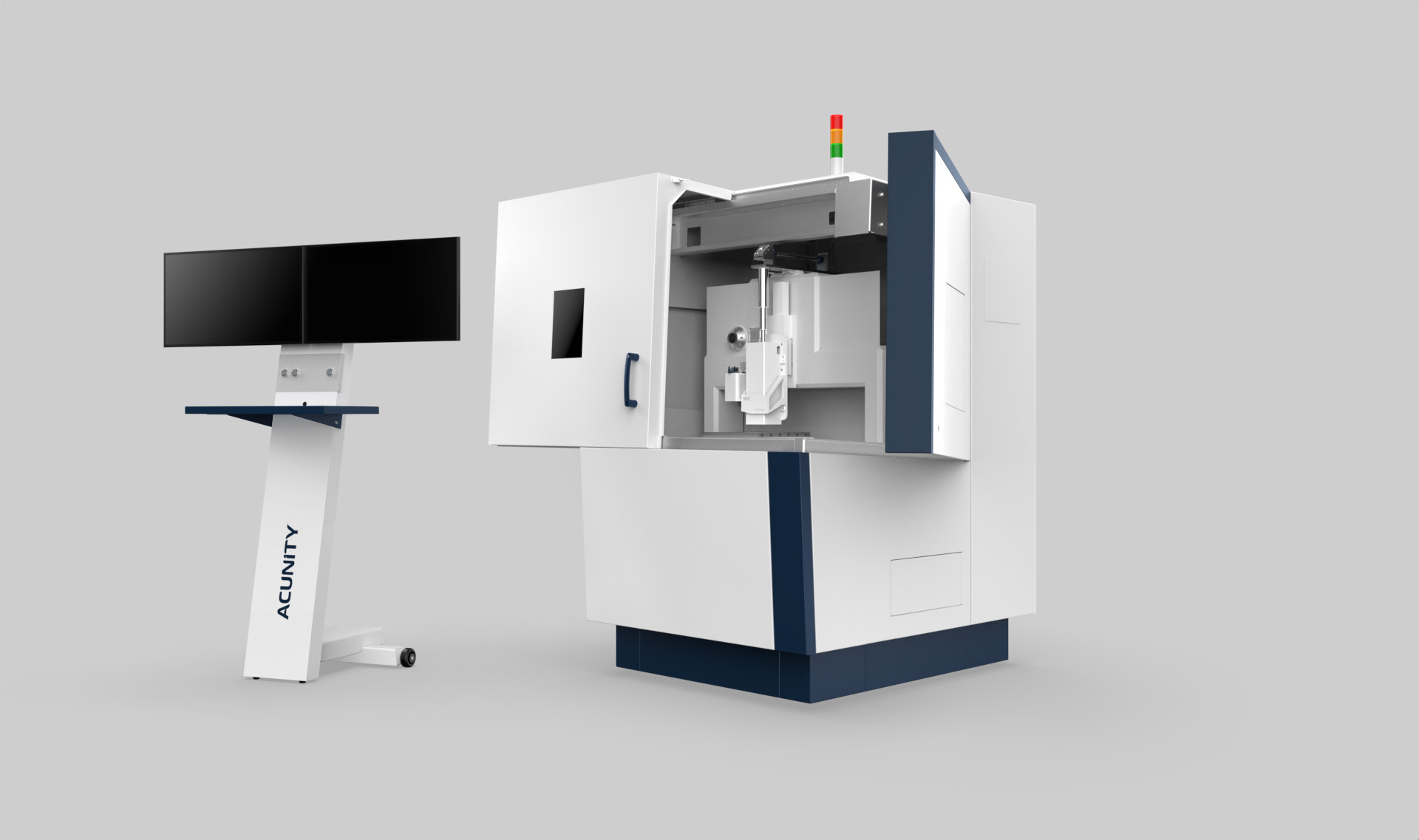

Laserbohren

Das Laserbohren mittels ultrakurz gepulster Laserstrahlung und unter Verwendung von Spezialoptiken, wie der Wendelbohr-Laseroptik, ermöglicht das Bohren jeglicher Materialien mit höchster Präzision und Qualität. So können Lochgeometrien wie Durchmesser und Konizität selbst für kleinste Bohrungen im Bereich unter 20 µm bei hohen Aspektverhältnissen bis zu 1:30 (Bohrungsdurchmesser zu Materialdicke) stufenlos eingestellt werden. Diese Technologie kann analog auch für das Laserschneiden eingesetzt werden. Unsere modularen Anlagenkonzepte ermöglichen die Integration dieser Fertigungstechnologie in eine Vielzahl modernster Laserbearbeitungssysteme, welche auf die spezifischen Kundenanforderungen angepasst werden können.

Technologischer Hintergrund

Die Qualitätsanforderungen an die Aperturgröße und Spaltbreite beim Präzisionsbohren und -schneiden sind aufgrund des Technologietrends der Miniaturisierung immens gestiegen.

Systemintegration

Wir bieten Ihnen drei leistungsstarke Servicepakete: von der Integration hochtechnologischer Systeme und Komponenten in Ihr Unternehmen bis hin zur Auftragsfertigung.

Anwendung / Branchen

Mit dem Laserwendelstrahl-Bohren und -Schneiden sind komplexe und hochpräzise Bohrungen und Schnitte möglich, die in vielen Industriebereichen zum Einsatz kommen können.